Services

Crane Spares

Crane spares refer to the replacement parts and components used in cranes to ensure their continued operation and performance. Over time, crane parts can wear out due to constant use, heavy lifting, harsh environmental conditions, and general wear and tear. Keeping a stock of critical spares is essential for reducing downtime and maintaining the crane’s safety and efficiency.

Crane spares can be categorized into several types, depending on the type of crane, the operating environment, and the maintenance needs. Let’s dive into the key categories of crane spares and why they are important for crane maintenance.

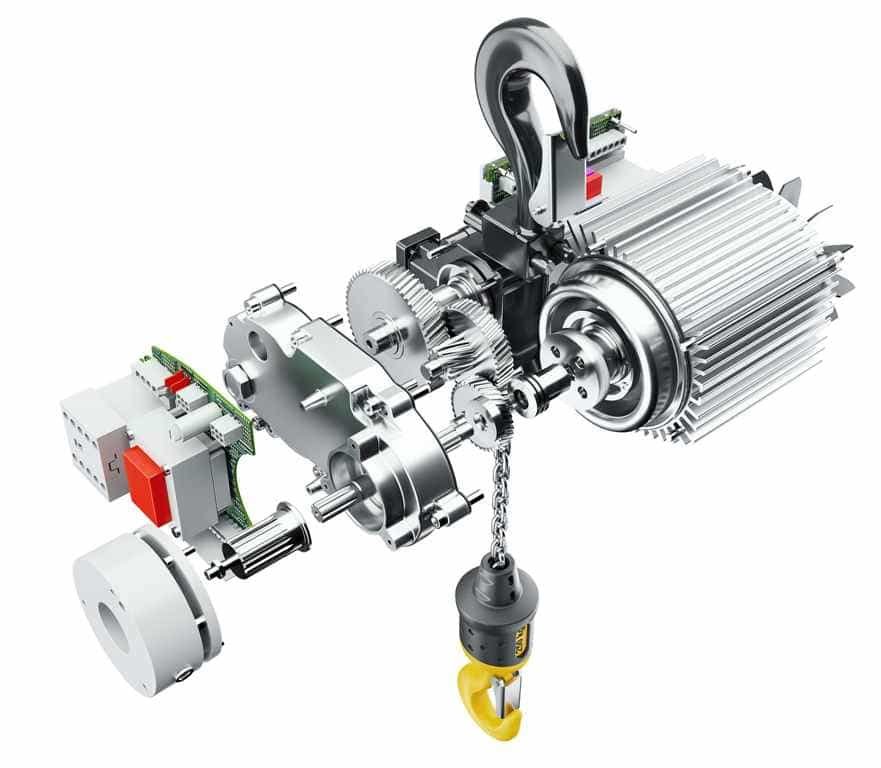

Hoist Mechanism Components

- Drum & Rope: The hoist drum is critical for winding and unwinding the wire rope, which is responsible for lifting and lowering loads.

- Wire Ropes: Over time, wire ropes can wear, stretch, or become damaged, requiring replacement. It’s crucial to monitor the condition of the ropes to avoid accidents.

- Sheaves and Pulleys: These are used in the crane’s lifting system to guide the ropes. They need to be kept in good condition to prevent excessive wear on ropes.

Gears & Bearings

- Gearboxes: Gearboxes convert the crane’s motor power into movement. Replacing worn-out gears or gearboxes helps maintain lifting efficiency and operational safety.

- Bearings: Bearings reduce friction in moving parts like the boom, hoists, and slewing rings. Worn-out bearings can cause unnecessary friction and strain, reducing the lifespan of the crane.

Hydraulic Components

- Hydraulic Pumps and Motors: Cranes with hydraulic systems rely on pumps and motors to operate key functions like lifting and boom extension. These parts need to be regularly inspected for leaks or wear.

- Hydraulic Cylinders: These cylinders are used to extend or retract the boom, outriggers, or other crane arms. They are critical to the crane’s lifting and positioning functions.

- Seals and Hoses: Hydraulic seals and hoses are often exposed to high pressures, chemicals, and extreme conditions. Over time, they can crack or degrade, requiring replacement.

Electrical Components

Control Panels and Wiring: Cranes depend on electrical systems to control motors, lights, and safety mechanisms. Faulty wiring, circuit boards, or electrical panels can lead to malfunctions, so keeping spares for key electrical parts is crucial.

Limit Switches: Limit switches control the movement of the crane by defining its operational limits. If a limit switch fails, it can result in the crane exceeding safe operational boundaries.

Safety Components

Overload Protection Devices: Cranes must be equipped with overload protection to prevent lifting beyond safe limits. Spare parts for these devices may include load cells, safety valves, and pressure relief systems.

Emergency Stops & Safety Brakes: Safety brakes and emergency stop systems are crucial for stopping crane operations instantly in case of malfunction. These parts should be regularly inspected and replaced if they show signs of wear.

Safety Glass and Lighting: Cranes require safety glass (for operator cabins) and external lighting systems. Cracked glass or malfunctioning lights can impact crane visibility and safety during operations, especially at night or in adverse weather conditions.

Structural and Wear Parts

Track Pads & Undercarriage Components (for Crawler Cranes): For crawler cranes, the tracks, undercarriage, and track pads experience heavy wear due to constant movement and the weight of the crane. Regular replacement of these parts is essential for maintaining mobility.

Outriggers and Stabilizers: Outriggers support the crane when it’s lifting heavy loads. The pads, cylinders, and structural components of outriggers can wear out and must be replaced periodically.

Types of Crane Spare Parts Suppliers

When sourcing crane spare parts, crane owners and operators typically work with suppliers that specialize in the following:

Original Equipment Manufacturers (OEM): OEM parts are made by the same manufacturer that produced the original crane. These parts are often the most reliable and maintain the crane’s warranty conditions.

Aftermarket Suppliers: Aftermarket parts are produced by third-party manufacturers. While they may not always meet the same standards as OEM parts, they can often provide a cost-effective alternative without compromising performance.

Local Distributors and Dealers: Local crane dealers often stock essential spares, making them a convenient option for quickly obtaining commonly needed parts.

Online Platforms: Many online platforms offer crane spare parts, allowing for easy comparison of prices and part availability. However, careful attention should be paid to the source’s reputation and the quality of parts.

Managing Crane Spare Parts Inventory

For optimal crane maintenance, having an organized and well-managed spare parts inventory is key. Here are some best practices for managing crane spares:

Categorize Parts by Type and Function: Classify crane parts into groups like mechanical, electrical, safety, and structural to easily locate the required part when needed.

Monitor Usage: Track the consumption and replacement rates of spare parts to identify which parts need to be stocked up in advance and which parts have a longer lifespan.

Keep Critical Spares On-Hand: Focus on maintaining a stock of parts that are most likely to wear out or fail, such as hydraulic seals, ropes, bearings, and control components.

Supplier Relationships: Establish strong relationships with reliable suppliers to ensure quick access to high-quality parts when needed. Having multiple suppliers ensures that you’re not reliant on one source in case of delays or shortages.

Set Reorder Points: Define reorder levels for each part to ensure that spares are replenished before they run out, avoiding delays in case of emergency repairs.